At Coastal Air Systems Marine, we get a lot of questions about how marine A/C systems actually work, and it’s a good one! If you’ve ever wondered how your boat stays cool even in the sweltering heat of a South Florida summer, here’s the breakdown.

How Marine Air Conditioning Systems Work for Boats (up to 150 ft)

Marine air conditioning works a lot like the unit in your house or car, but instead of dumping heat into the air, we dump it into the ocean. Seriously. Your A/C pulls heat out of the cabin using a closed-loop refrigerant system. That refrigerant absorbs the warm air inside and sends it to a heat exchanger where it’s released into the seawater outside.

To make that happen, a seawater pump pulls cool water from a through-hull fitting, runs it through the condenser coil to carry the heat away, and then sends that warmed water right back overboard. It’s a slick, efficient setup that lets us push cabin heat out to sea and keep the inside of your yacht cool and comfortable, no matter how hot it gets dockside.

What are the Primary Components of a Marine A/C System?

A marine A/C system consists of several primary components that work together in a refrigeration cycle to cool (or heat) the cabin. Each one has a specific job to do, and when everything’s dialed in your cabin stays cool, quiet, and comfortable. Here’s how it all works together:

-

Compressor: This is the heart of your A/C system, and it does some heavy lifting. The compressor pressurizes the refrigerant gas, heating it up and raising the pressure. This hot, high-pressure vapor is what we send to the condenser to dump its heat.

-

Condenser: Unlike a home system that uses air, we rely on seawater to cool things down. The condenser is a heat exchanger where the refrigerant gives up its heat to cool seawater that we pump in from the ocean. As the seawater absorbs the heat, the refrigerant condenses from a vapor into a warm liquid, and the now-warmed seawater gets pumped right back overboard. Efficient and ocean-friendly.

-

Expansion Valve: This is where the magic happens. The expansion valve (or cap tube/orifice, depending on the setup) meters out the liquid refrigerant and drops its pressure, which causes a big drop in temperature. That cold, low-pressure refrigerant is now ready to start cooling your cabin.

-

Evaporator: Located inside the cabin air handler, the evaporator coil is where your comfort really begins. Warm cabin air gets pulled over the cold evaporator, and the refrigerant inside absorbs that heat as it evaporates (boils). The result? Crisp, cool air flowing back into the space, and refrigerant that’s now a low-pressure vapor, carrying all that heat away.

-

Blower Fan (Air Handler): The blower keeps the air moving. It pulls in warm cabin air through a return grille, passes it over the evaporator coil, and pushes the cooled air back out through vents. It’s what makes the whole system feel seamless and keeps your interior evenly cooled.

-

Seawater Pump and Circuit: This part’s critical. Since the condenser depends on water to get rid of heat, we use a raw-water pump to pull seawater in through a thru-hull fitting below the waterline. That setup includes a seacock (shut-off valve) and strainer to catch any debris. The pump pushes the seawater through the condenser, where it picks up heat from the refrigerant, and then sends the now-warm water overboard through another thru-hull outlet. The whole circuit (intake, valves, pump, hoses, strainer, and outlet) has to be flowing smoothly whenever the A/C is running.

What is the Electrical Power Requirement for Marine A/C Units?

Let’s talk juice, because marine A/C systems definitely need it. These units pull a fair amount of power, which usually comes from your shore power hookup or your onboard generator.

Smaller to mid-size A/C units (in the 5,000 to 16,000 BTU range) typically draw about 4 to 13 amps when running on 115/120V AC power, pretty standard for North American boats. If you’ve got a single cabin unit, you’re probably in that range.

But as soon as you start scaling up (larger units, multiple zones, or big chillers) you’re going to need more current. That’s why a lot of bigger yachts run on 230V systems, or even split-phase 120/240V shore power. It helps handle the heavier loads from larger compressors without pushing the amperage through the roof.

Thermostats & Controls: How You Keep the Cabin Comfortable

Your marine A/C system doesn’t just run full blast all the time, it’s controlled by a thermostat, just like your home HVAC system. These thermostats (or digital control panels) are mounted in each zone or cabin and let you dial in your perfect temperature. Some give you even more control, like fan speeds or operating modes.

Once you set your desired temp, the thermostat does the rest. It monitors the cabin air and kicks the system on when things warm up – activating the compressor, seawater pump, blower fan, and any needed valves to get the cooling cycle going. When the space hits your setpoint, the thermostat shuts the compressor and pump back off, while the fan may keep running on low to circulate air evenly.

Most modern marine thermostats are digital, which means you get more precision, smarter system monitoring, and instant feedback. They’ll even throw up fault codes if something’s off, like low water flow or a refrigerant issue, so you’re never guessing why your cabin’s getting warm.

At Coastal Air Systems Marine, we install and troubleshoot these systems all the time. If your controller’s acting up or you’re ready to upgrade to something smarter, we’ve got you covered.

The 3 Common Marine A/C Configurations

Not all marine A/C systems are built the same, and that’s a good thing. Depending on your yacht’s size, layout, and cooling needs, there are a few main types of A/C setups you’ll run into: self-contained units, split systems, and chilled-water systems. All three work off the same refrigeration principles, but the way they’re installed (and what they’re best suited for) varies quite a bit.

Here’s how we break them down:

1. Self-Contained Units

This is the go-to setup for smaller boats or individual cabin cooling. Everything (compressor, condenser, evaporator coil, blower, and electronics) is built into one compact unit. We typically install these under a bunk, inside a locker, or tucked beneath a settee.

These units connect to the seawater cooling circuit and require ducting for air distribution. Because everything’s in one box, they’re simple to install and maintain. They’re ideal for boats around 20–40 feet, and some larger vessels also use them to cool specific zones or cabins.

Most self-contained units today are reverse-cycle heat pumps, which means they can cool you down in summer and warm you up in cooler months by reversing the refrigerant flow. They use modern refrigerants like R-410A or R-417A and usually come as turnkey packages.

Best for: Boats under 40 feet or single-zone applications

Perks: Easy install, all-in-one design, cooling and heating

Limitations: Slightly noisier due to all components being cabin-side

2. Split Systems (Remote Condenser Units)

In a split system, we separate the noisy, heat-generating parts from the living space. The compressor and condenser go in a machinery space (usually the engine room or a dedicated locker) while the air handler (evaporator + blower) goes in the cabin.

We run insulated copper refrigerant lines between the two, and boom.. you get quiet, efficient cooling without the hum of a compressor in your salon. These setups are great for mid-sized boats in the 40–80 foot range, and we often install them with multiple zones.

One condenser can usually handle more than one evaporator, giving you flexibility to cool different cabins or areas while keeping everything tied to a single compressor. Seawater cooling is still required, but one pump can often serve multiple condensers.

Best for: Boats 40–80 feet

Perks: Quieter cabins, centralized compressors, multiple-zone capability

Limitations: More complex install, needs refrigerant line routing

3. Chilled-Water (Chiller) Systems

This is the big-league setup, typically found on yachts 80 feet and up. Instead of running refrigerant to each cabin, we chill a fresh-water and glycol mix in a central chiller unit (or bank of units). That cold water then circulates through insulated plumbing to air handlers in each cabin.

Each air handler uses that chilled water to cool cabin air, kind of like a radiator setup. After picking up heat from the room, the water returns to the chiller to get cooled again. This setup allows super flexible zoning, ultra-quiet cabins, and big-time cooling power.

We like chilled-water systems for larger yachts or boats with complex layouts that need serious climate control across multiple spaces.

Best for: Yachts 80+ feet or multi-zone, high-end setups

Perks: Quietest, most customizable, scalable for large vessels

Limitations: Higher upfront cost, more plumbing involved

How long do marine air conditioners last?

We get this question a lot, and the honest answer is: it depends. Most marine A/C units last anywhere from 8 to 12 years, depending on how often you use them, where your boat lives, and how well the system’s taken care of.

Factors that affect lifespan:

-

Saltwater exposure: Even with corrosion-resistant components, salty air and moisture can still eat away at your system. Especially if it’s installed in a cramped or poorly ventilated spot.

-

Regular Maintenance: Units that get routine TLC (like cleaning filters, flushing seawater strainers, and descaling coils) will usually last a lot longer. We recommend descaling at least once a year.

-

Proper Installation: If your system was sized right for the boat and installed with good airflow and water flow, it won’t have to work as hard, and that means fewer breakdowns over time.

-

Usage frequency: If you’re a full-time liveaboard or run a charter that keeps the A/C cranking daily, your system’s going to age faster than someone who just hits the water on weekends.

Pro Tip: The compressor is the heart of the system, and when it goes (especially after 10+ years), it’s usually smarter to replace the whole unit than try to patch it up.

Want to stretch your A/C’s lifespan? Let us handle the maintenance so you’re not sweating over costly repairs down the line.

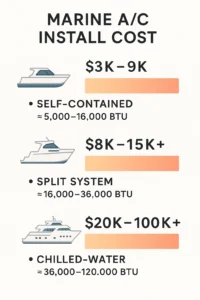

How much does it cost to install a marine A/C unit?

Installing marine A/C isn’t one-size-fits-all, it depends on the size of your boat, the type of system, and the layout. But to give you a ballpark, here’s what you can expect for a typical full install (parts + labor):

Typical cost ranges (parts + labor):

|

Boat Type / System |

Total Installation Cost |

|---|---|

|

Small self-contained unit (6k–12k BTU) |

$3,000–$6,000 |

|

Larger self-contained (16k–24k BTU) |

$5,000–$9,000 |

|

Split system (mid-size yacht) |

$8,000–$15,000+ |

|

Chilled water system (80+ ft yachts) |

$20,000–$100,000+ |

What’s included in that price?

When we do an install, we don’t cut corners. Your total cost usually covers:

- The A/C unit itself

- Electrical wiring, breakers, and safety components

- Seawater plumbing (pump, strainer, thru-hulls)

- Ducting and vents for air distribution

- Thermostat/control panel install

- Full professional labor (clean, safe, and done right)

Can You DIY It?

Some seasoned boat owners handle their own installations, especially for smaller self-contained units. If you’re comfortable with marine-grade electrical and plumbing work, it can be a way to cut costs. Just be sure you follow safety standards to the letter, bad wiring or a leaky pump setup can cause serious problems down the line.

Need help figuring out what kind of setup fits your boat and your budget? We’re happy to walk you through the options and give you a quote that’s clear and pressure-free.

Do you need to service AC every year?

Short answer: Yes. And if you’re using your system year-round, especially in warm, salty climates like here in South Florida, twice a year is even better.

Routine maintenance keeps your A/C running at peak performance, prevents expensive failures, and helps you avoid sweating through a weekend on the water.

Here’s What Annual Service Should Include:

-

Cleaning or replacing the air filters

-

Flushing the seawater circuit with descaler to remove calcium and lime buildup

-

Cleaning the seawater strainer

-

Checking hose clamps and seawater lines for leaks or corrosion

-

Checking electrical connections and the thermostat

-

Testing cooling performance and airflow

-

Checking refrigerant pressures, if accessible

What Happens If You Skip Maintenance?

Letting your system go unchecked can lead to:

-

Overheating from clogged seawater lines

-

Mold or mildew inside your ductwork

-

Compressor burnout due to poor heat exchange

-

A big drop in cooling performance, just when you need it most

Pro Tip: Regular maintenance means fewer surprises, lower energy bills, and longer life for your system. Plus, your boat stays cool when it matters most.

Need help setting up a maintenance schedule? We offer seasonal checkups that keep everything running smooth, just give us a call.

How Do You Maintain a Marine A/C System?

Just like your engines, your A/C system needs routine maintenance to keep it running strong, especially during the heat of the season. Whether you’re living aboard or cruising on weekends, a regular upkeep schedule will help prevent breakdowns, extend the life of your unit, and keep your cabin cool when it counts.

Here’s how we recommend staying on top of it:

1. Weekly to Biweekly (While You’re Actively Using It)

Start with simple tasks that can prevent major issues later:

Clean the return air filters

Pop them out and rinse with fresh water. Dirty filters choke airflow and can cause your system to freeze up or overwork itself.

Check seawater flow

Take a look at the overboard discharge. You should see a solid, steady stream. If it’s weak or pulsing, you might have a clogged strainer or an issue with the pump, both of which can lead to overheating.

2. Monthly Checks

Every few trips or once a month, take time to:

Clean the seawater strainer

Pull the basket and give it a rinse to clear out seaweed, shells, or gunk. A blocked strainer is one of the top causes of compressor failure.

Inspect hoses and clamps

Look over your seawater lines for signs of corrosion, wear, or slow leaks. Better to catch issues early than replace a flooded bilge fan later.

Wipe down the unit

Salt air and grime can collect fast. A quick wipe-down helps prevent corrosion and keeps components breathing easy.

3. Annual or Seasonal Maintenance

At least once per year, or at the start of boating season, conduct a more thorough inspection and cleaning:

Flush the seawater circuit

Use a marine-safe descaler (like Barnacle Buster or Rydlyme) and a small pump to flush out any mineral buildup in the condenser. This step keeps heat exchange efficient and prevents system strain.

Clean the evaporator coils

Dust and dirt on the evaporator reduce airflow and cooling power. Brush or vacuum the coil gently, no need for chemicals here.

Inspect all electrical connections

Check terminals, wiring, and control boards for corrosion or loose connections. Electrical issues are a silent killer if left unchecked.

Test system performance

Run the A/C through a full cycle: make sure it’s cooling properly, blowing strong, and not making weird noises or throwing out odors.

Check refrigerant

If the unit isn’t cooling like it used to, it may be low on refrigerant or have a leak. That’s something we can check and recharge as part of a full A/C system diagnostic.

When to Call for Service or Start Troubleshooting

Your A/C is trying to tell you something if you notice any of the following:

- Weak cooling or warm air from the vents

- No water discharging overboard

- Frequent shutdowns or error codes

- Ice building up on the evaporator coil

These are all red flags pointing to possible airflow issues, blocked seawater flow, or refrigerant pressure problems. If something feels off, don’t wait. It’s always better to catch a small issue before it turns into a big (and expensive) one.

Maintenance Tips from the Coastal Air Systems Crew

Want to keep your system running smooth and extend its lifespan? Here are a few of our go-to tips:

-

Install a soft start module: It’ll ease the startup load on your compressor and reduce stress on your boat’s electrical system, especially helpful with limited shore power.

-

Use a seawater strainer with a clear bowl: Makes it easy to spot clogs or growth at a glance, no guessing required.

-

Label your seacocks: In an emergency, everyone aboard should know how to shut off the system fast. Practice this just like a fire drill.

- Descale your system regularly: Marine growth and mineral deposits don’t stand a chance with a proper flush routine.

A little preventative care goes a long way. Keep your system clean, your flow strong, and your controls sharp.. and your A/C will deliver cool, reliable comfort all season long!